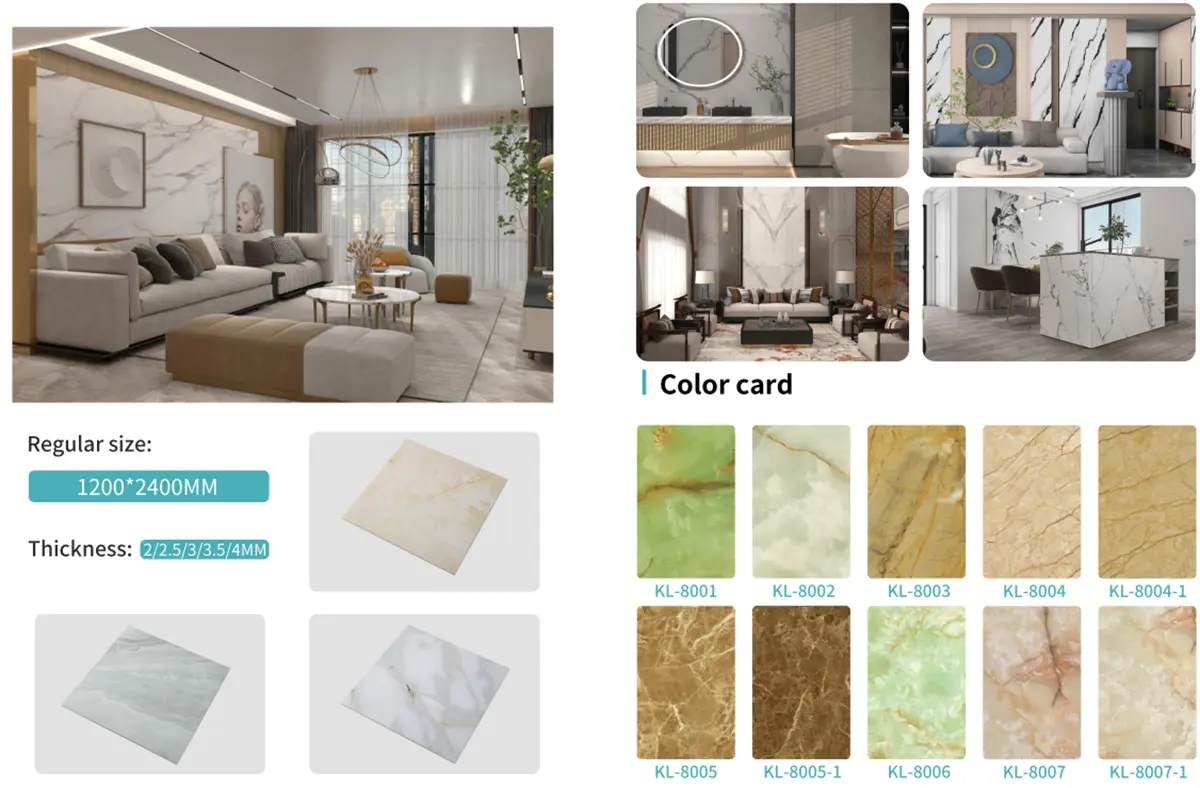

The most popular board to replace marble-UV board

UV board is a board with a UV protected surface, as the name suggests. Next, I would like to take you to understand why the UV board is so popular with the general public?

UV board is a board made by adding UV varnish to the surface of ordinary wooden boards. The varnish is then dried using a UV light curing machine. It has the advantages of smooth surface, bright color, strong wear resistance, non-toxic and environmental protection, good moisture resistance, and not easy to deform. This means that the UV Board is designed to last for a long time and to provide high practical value.

UV panels add UV colour onto external surfaces. These are UV curable coatings, also known as photoinitiated coatings. Solvent-free, non-volatile, non-toxic and environmentally friendly 4E green high quality paint is used for the primer; Once cured, it has a high gloss antibacterial effect. Usually the paint is not good and there is a constant release of volatile organic compounds (VOCs).

UV board is made by applying UV paint to the board, such as some particleboard and density board. This is then dried using a UV curing machine. Its ease of processing makes it suitable for industrial production. UV panels have a long service life and are subject to high levels of mechanical and process engineering requirements. It is also an ideal decorative panel as it is resistant to moisture and deformation.

Conventional UV panels are generally resistant to the corrosion caused by a variety of acidic and alkaline disinfectants. The above characteristics of the ultraviolet board is due to the chemical reaction between the coating and ultraviolet light, forming a dense protective film, and the density of the dense protective film is very small, the density of the protective film is less than the density of some molecules, such as water molecules, acetic acid molecules, etc. This means that it is waterproof, anti-fouling and resistant to corrosion from both acids and alkalis.

UV panels are also designed to help protect the environment. The paint is not good and volatile organic compounds (VOCs) are constantly released compared to conventional painted substrates. UV panels, which do not contain volatile substances such as benzene, solve this environmental problem. And with the ultraviolet curing process, a dense cured film is formed to reduce the amount of gas released by the substrate.

Markets for UV panels, such as the cabinet industry, have been created by the benefits of UV panels. Wooden doors in a variety of materials are dazzling with the development of China's cabinet industry. News of excessive formaldehyde in cupboards is very common, despite the variety of wood door panels available. When choosing materials for the kitchen, more attention should be paid to safety and cleanliness than to decorating materials used in ordinary rooms. This is why UV panels are the majority choice in the market for cabinet materials.