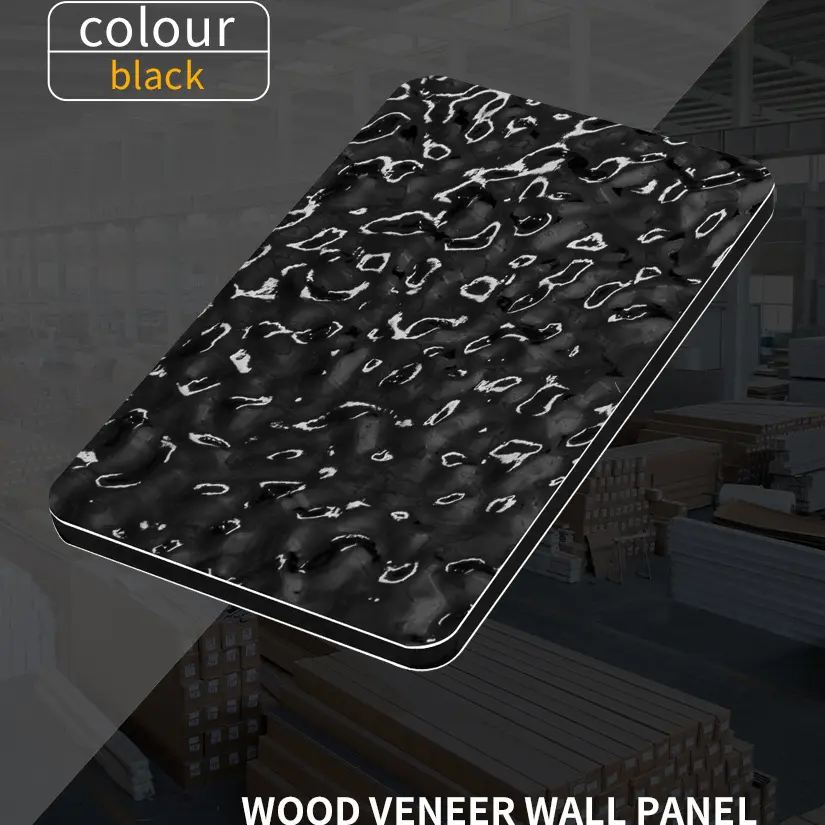

Home Interior Decoration Bamboo Charcoal water ripple wood veneerl

Wooden decorative panel

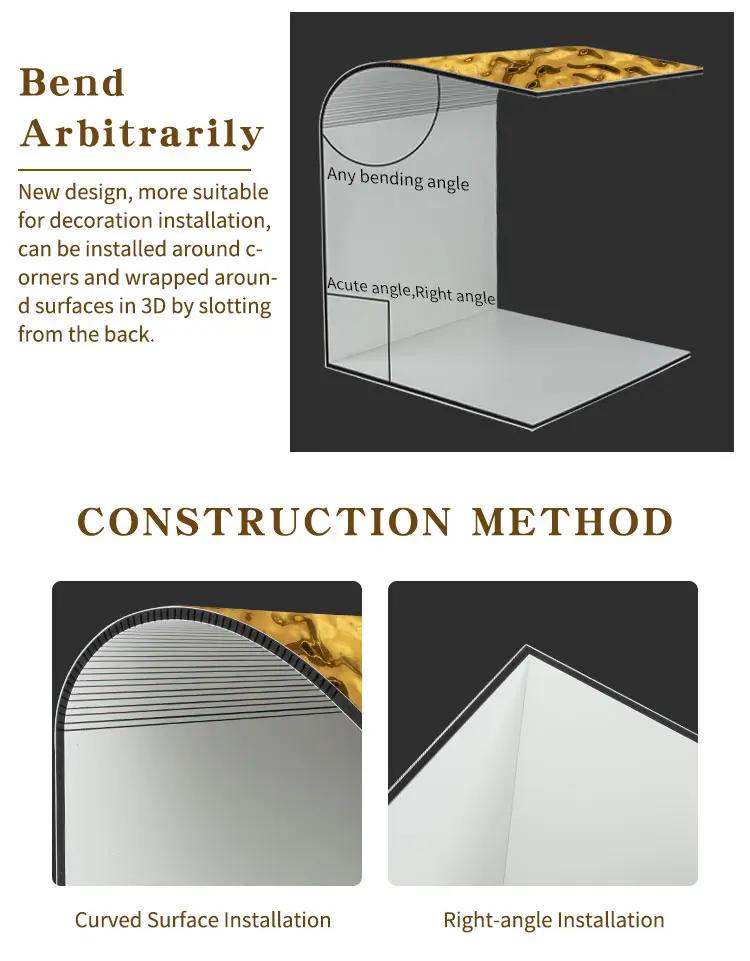

Applying veneer to the surface of different substrates can present the patterns and colors of solid wood. Common wood veneers include teak, walnut, maple, and water chestnut.

advantage

Because it is directly made of natural wood, the wood veneer is authentic, natural, without cracking or deformation. It can be made into various finishes and baked paints, suitable for furniture of various styles.

shortcoming

The price is relatively high, the wood grain styles are limited, and the maintenance is also complicated. The solid wood veneer is prone to warping or cracking. The durability is poor, and it will cause the veneer to peel off after being impacted.

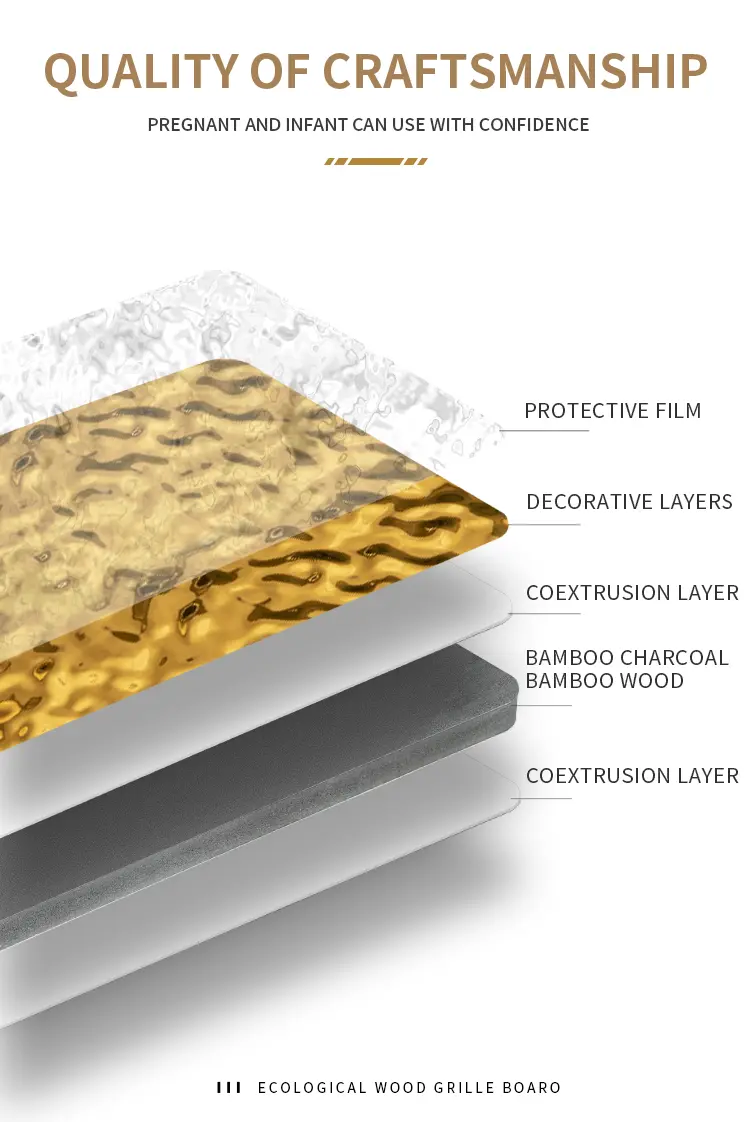

Plastic veneer (Polymer coated film, vacuum formed board, PVC board)

Common plastic finishes include softer polyvinyl chloride film, also known as PVC, which is one of the most commonly used finishes in cabinet customization. Suitable for concave surface forming. The most commonly used for packaging various shapes of medium density fiberboard.

advantage

PVC film is thick, with a variety of styles and affordable prices. PP

Resin film, the board surface is more realistic, and the board surface is waterproof and moisture-proof, anti-aging and wear-resistant, and does not fade after a long time of strong light exposure.

Compared to PP material films, both are more environmentally friendly and healthy.

shortcoming

The manufacturing cost of PVC film is high, and the overall shape is not good

The face is relatively fragile, and I am afraid of cigarette burns and scratches from sharp objects.

Paper veneer

Also known as double decorative panel, it is made of decorative paper with patterns. There are many types of paper veneer panels, and the main substrates are mostly decorative boards and plywood.

advantage

It can imitate various textures. Relatively wear-resistant and able to resist general abrasion. Good heat resistance, moisture and moisture resistance, flat and not easily deformed, economical price.

shortcoming

Edge sealing is prone to breakage and there are obvious traces of glue. If the edge sealing is not done properly, the bonding between the edge sealing strip and the board body will not be tight, and formaldehyde will overflow more to the outside, which is not environmentally friendly and unhealthy.

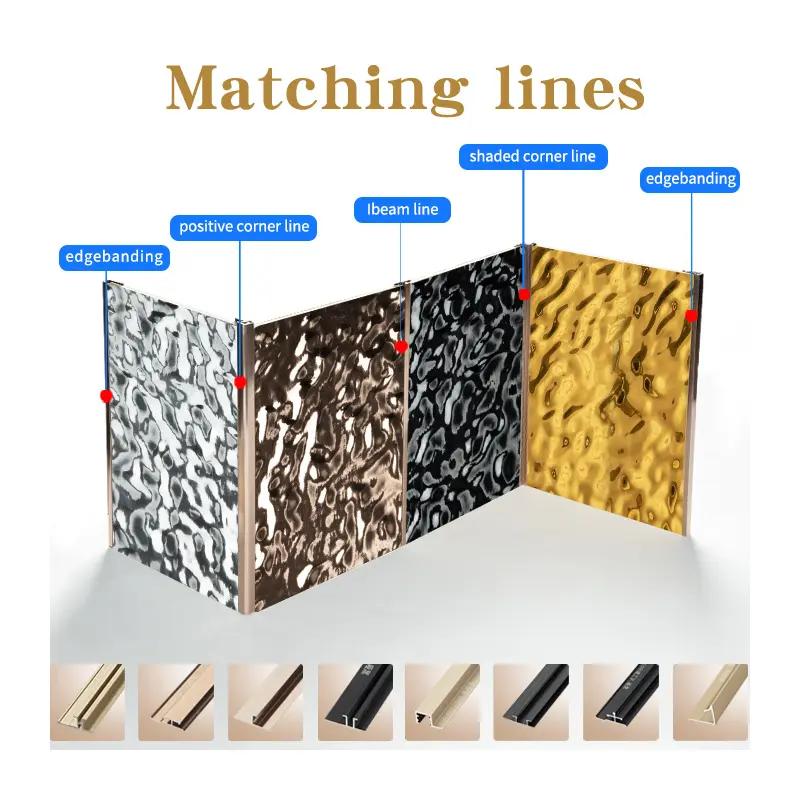

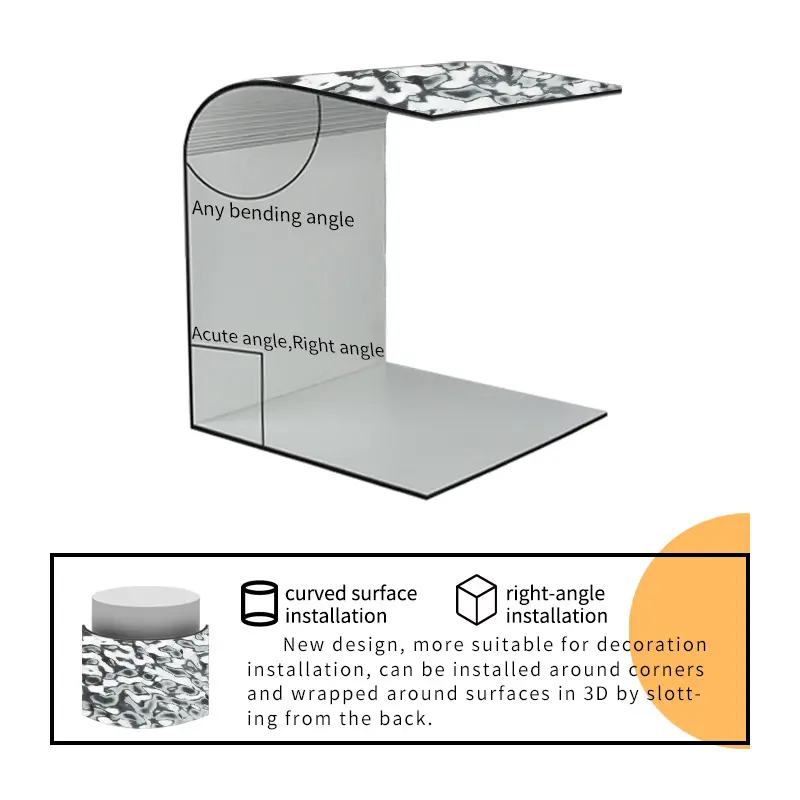

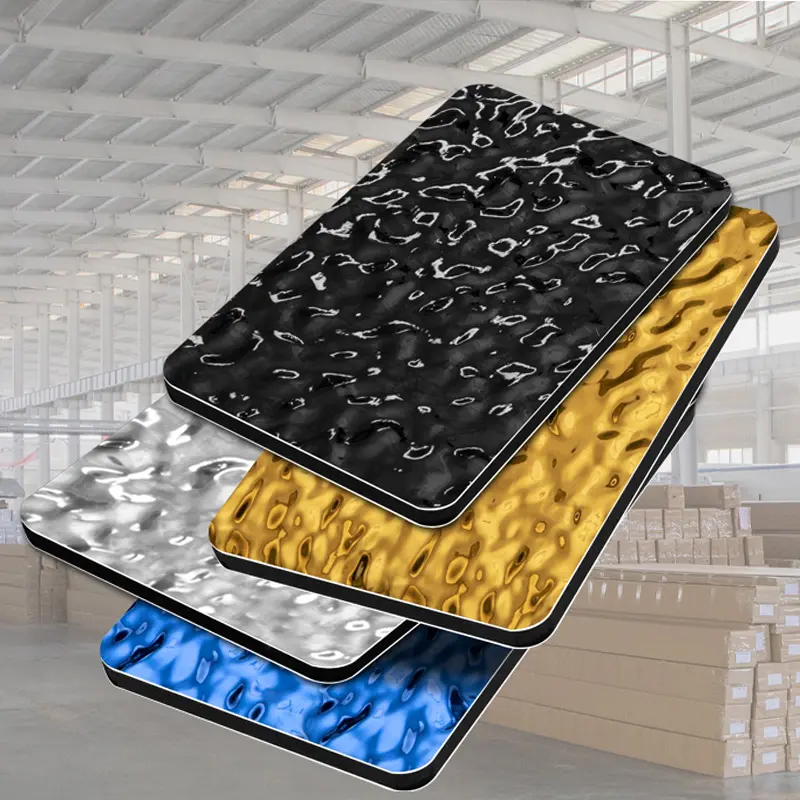

product Display

Exhibition show

certificate & honors