As the demand for hygiene and cleanliness increases in various industries, PVC Hygienic Wall Cladding emerges as a critical solution. Reports indicate that the global market for PVC wall cladding is projected to grow significantly, reaching approximately $1.2 billion by 2026. This surge is driven by industries such as healthcare, food processing, and cleanrooms, which prioritize sanitary environments.

PVC Hygienic Wall Cladding provides durable and easy-to-clean surfaces. Its resistance to moisture and bacteria makes it a popular choice. However, not all options are equal. Some may fade or discolor over time, which could lead to increased maintenance costs. Choosing the right cladding involves considering factors like thickness, design, and installation methods.

Many facilities still overlook essential aspects when selecting PVC Hygienic Wall Cladding. They focus solely on cost, sacrificing quality and durability. This short-sightedness can result in significant long-term expenses. As we look toward 2026, understanding the best PVC Hygienic Wall Cladding options is vital for maintaining hygienic spaces effectively.

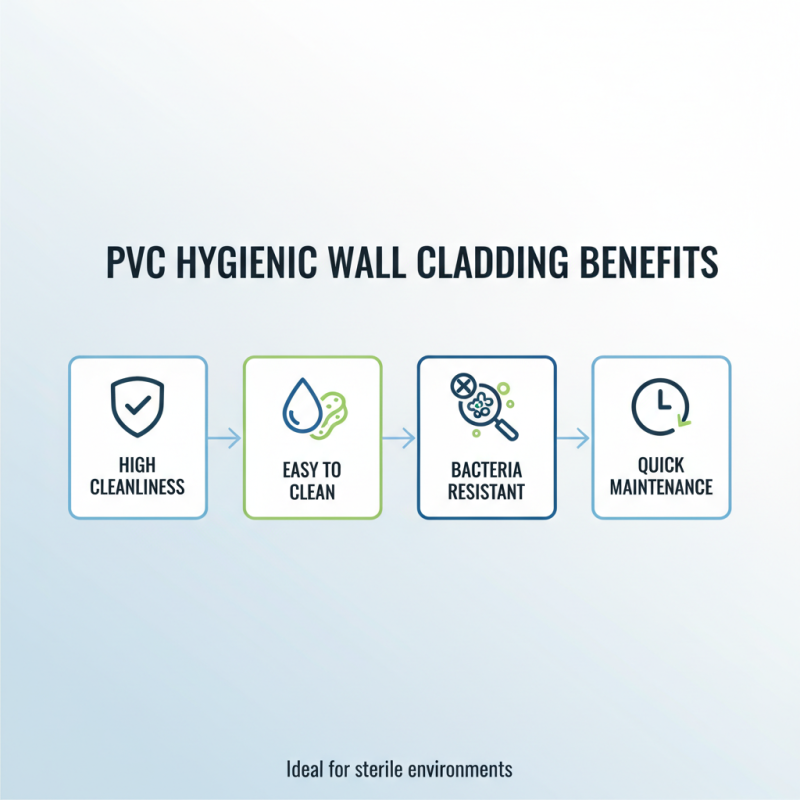

PVC hygienic wall cladding has gained popularity due to its numerous benefits. This material is an excellent choice for environments that require high cleanliness standards. Its smooth surface prevents the accumulation of dirt and bacteria. The ease of cleaning is a significant advantage, making maintenance simpler and faster.

Key features of PVC hygienic wall cladding include durability and moisture resistance. Unlike other materials, PVC does not absorb water, which helps prevent mold growth. It also withstands heavy impacts, making it suitable for high-traffic areas. Some finishes even resist chemicals, adding to its versatility. However, not all PVC wall cladding offers the same level of protection. Choosing the right thickness and finish is critical for optimal performance.

Color options and designs are also essential. They can enhance the aesthetic appeal of a space. However, it’s important to select colors that won’t fade over time. Some cheaper options may not hold up as well under UV exposure. This is a point worth reflecting on when deciding what to purchase. Balancing style with functionality is key.

In 2026, the standards for PVC hygienic wall cladding will focus on durability and cleanliness. Material selection will play a key role. The cladding should resist moisture and stains, ensuring long-lasting performance. The finish must be smooth to facilitate easy cleaning. A textured surface can trap dirt, which is a concern for hygiene.

Industry professionals will emphasize sustainability. New formulations of PVC may be eco-friendly while maintaining strength. The production process might evolve, producing less waste. Certifications will ensure products meet rigorous health and safety standards. Buyers should look for evidence of compliance with these standards in product specifications.

However, choosing the best option can be tricky. Not all suppliers will align with current regulations. It may require research and diligence. Relying on online reviews without verification can lead to issues. Packaging and marketing can be misleading. Investing time upfront can prevent costly mistakes later.

The field of PVC hygienic wall cladding continues to evolve, driven by the demand for sanitation and durability. A recent industry report indicated that the global market for PVC wall cladding is projected to grow by over 5% annually through 2026. Innovations are emerging to address specific hygiene needs, especially in healthcare and food processing sectors.

Several top manufacturers are now focusing on antimicrobial properties in their products. These advancements aim to inhibit the growth of bacteria and fungi, contributing to safer environments. A study showed that properly chosen materials can reduce microbial contamination by 80%. Yet, not every manufacturer prioritizes these features, leaving gaps in the market.

Color and design also play pivotal roles in client choices. Vibrant colors can enhance the ambiance of a space, making it welcoming. However, not enough emphasis is placed on how these choices impact psychological health. Some facilities overlook the importance of aesthetics in hygienic environments, which may lead to a sterile feeling. Ultimately, while progress is notable, there remains a constant need for greater awareness and improvement in various aspects of PVC hygienic wall cladding solutions.

PVC wall cladding has gained popularity due to its cost-effectiveness and ease of maintenance. According to industry reports, the global market for PVC wall cladding is projected to reach USD 12 billion by 2026. This trend highlights the material's growing acceptance over traditional options. PVC offers a waterproof surface, making it ideal for moisture-prone areas. Its lightweight nature eases transportation and installation costs.

When comparing PVC to other materials such as ceramic tiles and wood, several aspects emerge. Ceramic tiles are durable but labor-intensive to install. Moreover, they can crack under impact, leading to costly repairs. Wood, while aesthetically pleasing, often requires regular treatments to resist rot and pests. A study indicated that over 60% of facilities choose PVC for areas needing hygienic surfaces due to its non-porous nature, contrasting with the absorption issues in wood.

Despite its many advantages, PVC isn't without criticism. Concerns about sustainability and potential environmental impacts persist. Additionally, while PVC can mimic other materials, some users find it lacks the authenticity of natural finishes. This complexity invites further evaluation of preferences in material choice. What drives decisions in wall cladding can reflect broader industry shifts and demands.

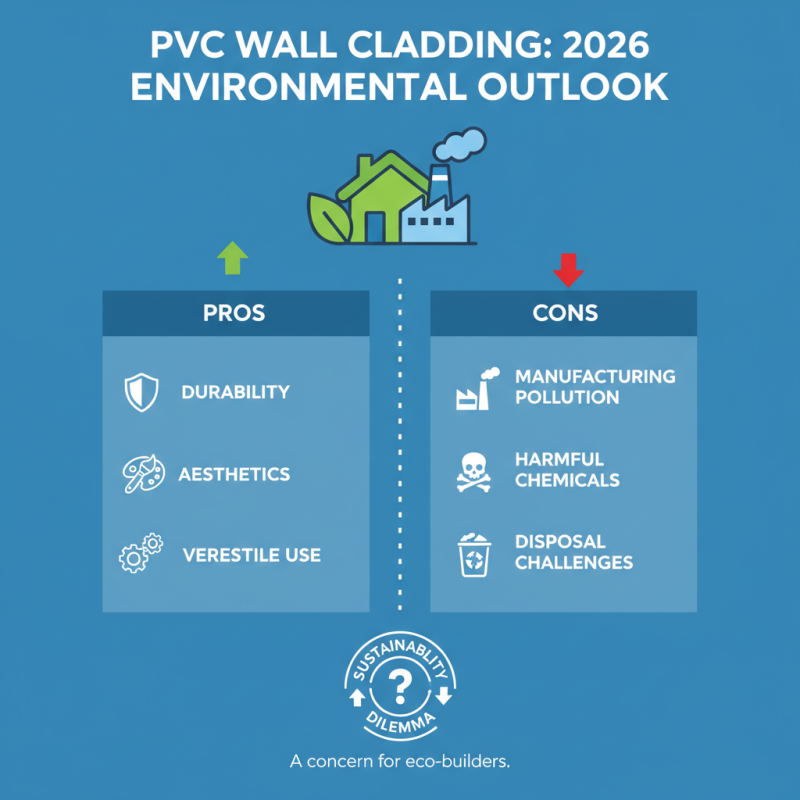

The environmental impact of PVC wall cladding continues to be a crucial topic as we approach 2026. PVC, or polyvinyl chloride, is widely used for its durability and aesthetic appeal. However, its production and disposal raise sustainability concerns. The manufacturing process often involves harmful chemicals and significant energy consumption. This is an ongoing dilemma for environmentally conscious builders.

Recycling PVC is challenging. While some facilities can process it, many simply do not recycle this material effectively. As a result, a large amount of PVC ends up in landfills. This creates a long-term problem for our environment. The development in alternatives could help mitigate these concerns. Biodegradable materials are becoming more popular.

As we think ahead to 2026, it's crucial to choose cladding wisely. Responsible sourcing and manufacturing practices are necessary. Producers should invest in eco-friendly options. However, there is a long way to go in making PVC a truly sustainable choice. Ongoing reflection on its life cycle is vital. Awareness can help drive the change we need for a greener future.